Unique detection capabilities

Food Radar Systems is a pioneering company in the detection of foreign bodies in food products. The company was founded after a research project involving the Swedish Institute for Food and Biotechnology (SIK), food manufacturers and Chalmers University of Technology paved the way for the idea. The patented Food Radar® technology was born out of a need to detect common food contaminants that could not be detected by existing technologies.

A new weapon in the fight against food contamination

Food safety must always be at the top of the industry’s agenda, and the removal of physical contamination is central to achieving that goal. Low-density foreign bodies such as shells, soft plastics and pit fragments, have always caused problems for the industry. The traditional methods of manual removal are simply insufficient to address this issue going forward, so the Food Radar® represents a new opportunity for the food industry.

Continous improvements

Working closely with our customers over the years, we have learned how their system design needs differ according to their unique factory conditions. This understanding led to the new Generation III Food Radar®, which can be easily and fully adapted to fit each customer's unique production line.

Hygienic design

All the electronics and modules are contained in one hygienic cabinet. Cables and connections to the system are also designed to meet the highest standards of hygiene and safety.

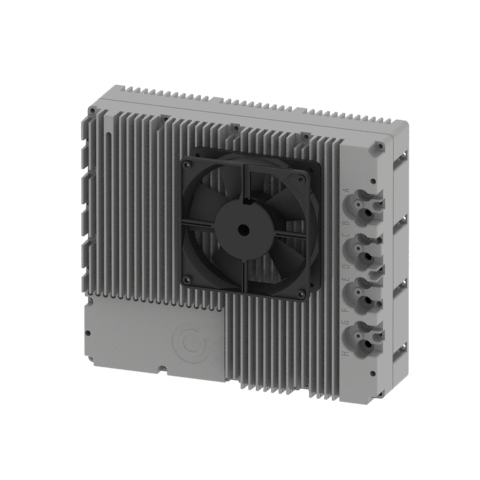

High speed microwave unit

Microwave technology derived from military applications for ultrafast measurements and durability. All enclosed in one rugged, purpose-built enclosure.

Robust microwave sensor

The microwave sensor is available in three pipe sizes, where microwave antennas are attached around the pipe to effectively

scan the product.

All system parts can be cleaned as part of the production line CIP cycle

where the Food Radar® is installed.

High-speed rejections

The actuator is optimized for high-speed contaminant removal and flips the reject valve in less than 100ms. This keeps product waste during every removal to an absolute minimum. The valve is 3A certified with a completely open cross section and is easy to clean and maintain.

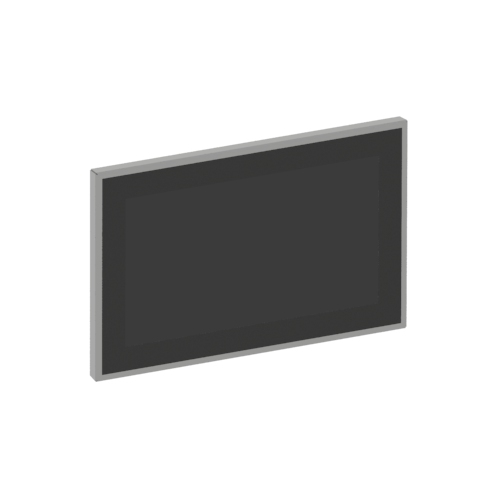

18.5" widescreen interface

The interface for the latest Food Radar® runs on an 18.5" widescreen touch monitor, all designed in hygienic

stainless steel. The screen can either be attached to the system or placed separately nearby if so desired.

The Food Radar® can be equipped with an OPC UA server module to allow for integration with an existing Industry 4.0 factory.